The Tuscany region, where Carrara originated, was the birthplace of the Italian Renaissance. It was used extensively by masters such as Leonardo da Vinci, Rodin and Michelangelo in their works. Carrara marble has light grey filigree, dots and fine grains, with elegant and noble texture and moist body, mostly used in interior decoration. For Carrara marble and Carrara marble-look tile, you may be very vague about the difference between them. Next will tell you how to choose the right Carrara for you.

What is Carrara?

Carrara is a natural stone from Italy. If Italy is the “country of marble”, then Carrara is the “capital of the country”. It is a rich treasure house of natural stone and the mecca of human art.

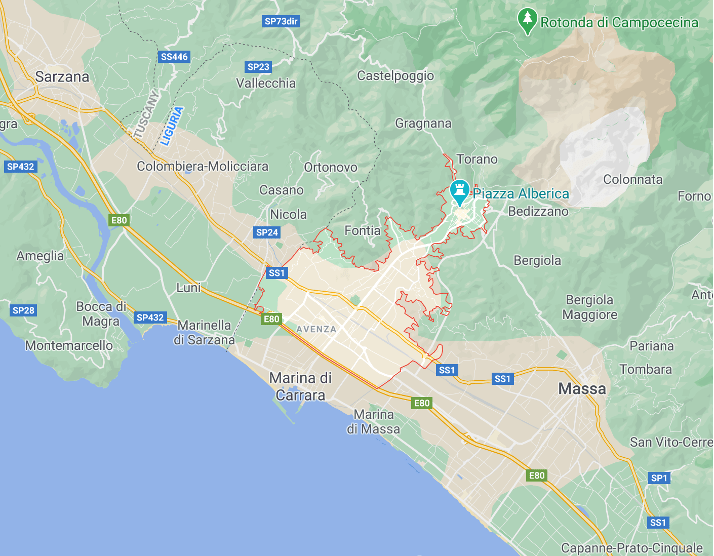

Carrara, located in the north-central region of Italy today. It is located in the foothills of the Apulian Mountains, 5 km west of the Ligurian Sea. With a population of only about 60,000, this town in the mountains and the sea is a small, authentic mountain town. However, please do not underestimate this city, because it has a history of more than two thousand nine hundred years.

The origin of the name “Carrara” has been described in two ways: from Latin, meaning “quarry”, and from Proto-Indo-European, meaning “rock”. Obviously, both names indicate that the fate of the city is closely linked to marble. Today, white stone is more and more widely used in a decorative design, Carrara marble is shown in the overall space; the attitude to life is pure, noble and bright. The famous Michelangelo has used Carrara marble to make world-famous statues such as Pietà and David.

Carrara marble is a white or blue-grey marble that is very popular for sculpture and decoration of buildings. It is quarried in the municipality of Carrara in the province of Massa and Carrara in Lunigiana, the northernmost tip of present-day Tuscany, Italy.

How the Carrara Marble-look tile produce?

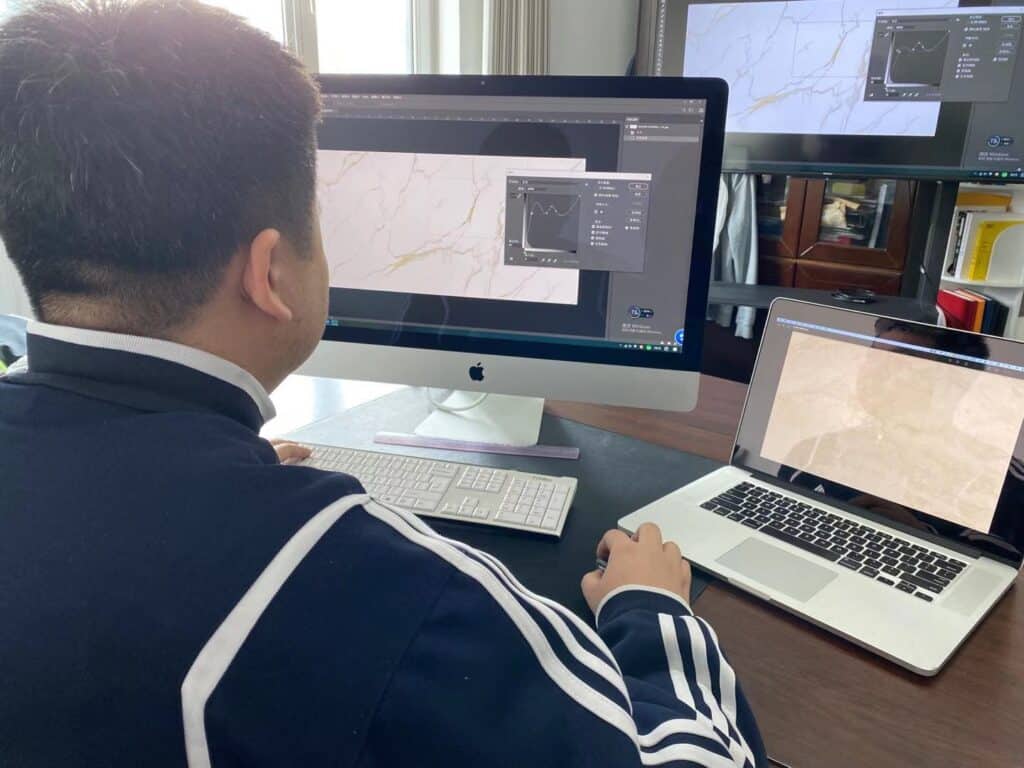

How does T&A Ceramics produce Carrara porcelain & ceramic marble-look tiles? We do not achieve the Carrara texture by artificially imitating it without any basis. First, we purchase real natural Carrara stone and scan it to get the real Carrara texture.

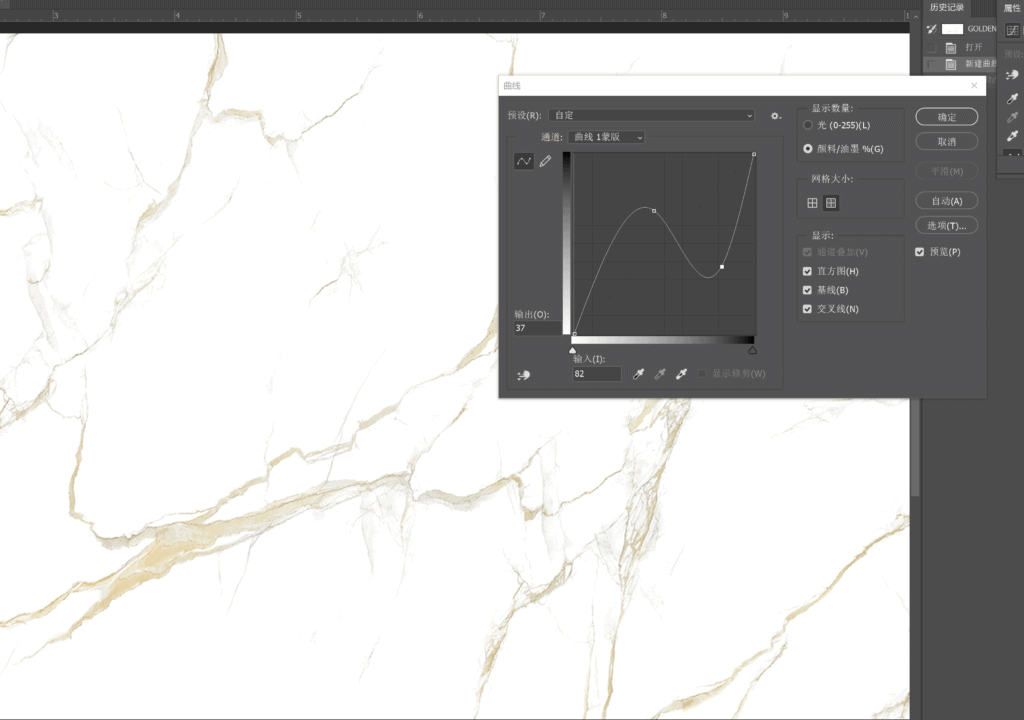

The designer then finishes the natural stone’s texture – removing the abrupt, untidy parts and making it more harmonious and comfortable. The result is the Carrara collection we present.

Many people may have questions, why do we need to go through the designer to retouch the texture we get? Our designers modify the grain because the Carrara marble grain is irregular, with the partial dense and partial sparse situation. When you are laying marble, you have to cut out the unattractive or abrupt parts. Then your workers have to follow the texture’s direction to screen and make a perfect laying plan. However, the Carrara texture we finally get after the designer’s modification and design is the texture that best meets your heart’s expectation, without uneven texture distribution, so that you can save time and effort in laying the tile.

If you have a special idea about the Carrara texture, you can also contact us, and we will let the designer make the Carrara unique to you according to your special requirements for the texture.

Next, the selected Carrara design will follow the production process. Here there are generally 10 production steps.

- Pressing – The prepared materials will be sent to the pressing process, where the raw material enters the mould and then a specific pressure is applied to it so that it is pressed into a tile body.

- Drying of the tiles – After pressing, the water content in the tile body is a lot, after the drying process is to evaporate the water so that on the one hand can improve the tile body’s strength. On the other hand, it can prevent the tile with high water content from breaking when fired in the kiln due to the violent evaporation of water.

- First glazing – The main role is to cover the tile body’s original colour and decorate the tile body.

- Inkjet printing – Printing with advanced inkjet printers to render the best Carrara texture.

- Secondary glazing – A layer of glaze applied after the printing, also known as protective glaze, after firing into transparent performance.

- Firing – After printing, the tiles are fired by firing in a high-temperature kiln (generally around 1200℃), we have a 400m kiln production line, which can make the firing time of the tiles more adequate, and the products after firing have lower water absorption, brighter and flatter tile surface, delicate without pinholes. The whiteness of the body is greatly improved. Even after grinding the edge, the billet layer’s side will not produce black edge phenomenon, and the product quality is fully guaranteed.

- Edges Trimming – This step is to trim the four edges so that they are smooth and not uneven, and in this step, the tiles are finalized in size.

- Polishing – As the name suggests, it is the process of polishing the surface of the semi-finished products calcined in the kiln to give them a certain glossy surface, and the products are shaped in this process.

- Super Clean – Super Clean Shine is an emerging special processing process. Super Clean Shine uses high-tech nano-materials to make products with a surface gloss of 90 degrees or more through grinding and filling varnishing. It’s anti-fouling ability is superb with excellent surface texture.

- Sorting – Sorting is the process of classifying the products produced in the previous processes according to colour and surface quality and is the final stage of the entire production process.

- Packaging – After sorting, the finished product is packaged for storage, and the entire production process is completed.

Through this paragraph, you may understand that the production of a tile piece is not so simple, high-quality tile often requires the cooperation of all aspects to achieve perfect results.

Carrara Marble vs Carrara Marble-look tile, the pros and cons.

Carrara marble

Pros: Carrara marble will be very beautiful after polishing, and each piece of texture is different, natural generation, smooth and delicate, can set off the home more elegant and generous.

And there are many advantages. One is the high hardness and not deformation; natural marble is after a long period of time. In the process of use, the organization of the natural structure of uniform will not deformation and cracking. Second, corrosion resistance, acid resistance and alkali resistance are very high. Thirdly, it will not be deformed and damaged at high temperature because of the change of temperature.

Cons: First of all, high-quality Carrara marble is very expensive and the high cost of processing is something you have to consider. And it is very fragile.

Carrara marble in the long formation process of nature, naturalness, although high, but the presence of heavy metals and other substances for a long time, more or less will have a certain degree of radiation.

And, there is the stain resistance is not too good, because there are natural voids, so it is easy to be contaminated, easy to breed bacteria, easy to oil seepage easy to be stained, for the decoration construction process will require a higher.

And Carrara marble will appear the possibility of yellowing; its cleaning and maintenance is also a tedious and time-consuming process.

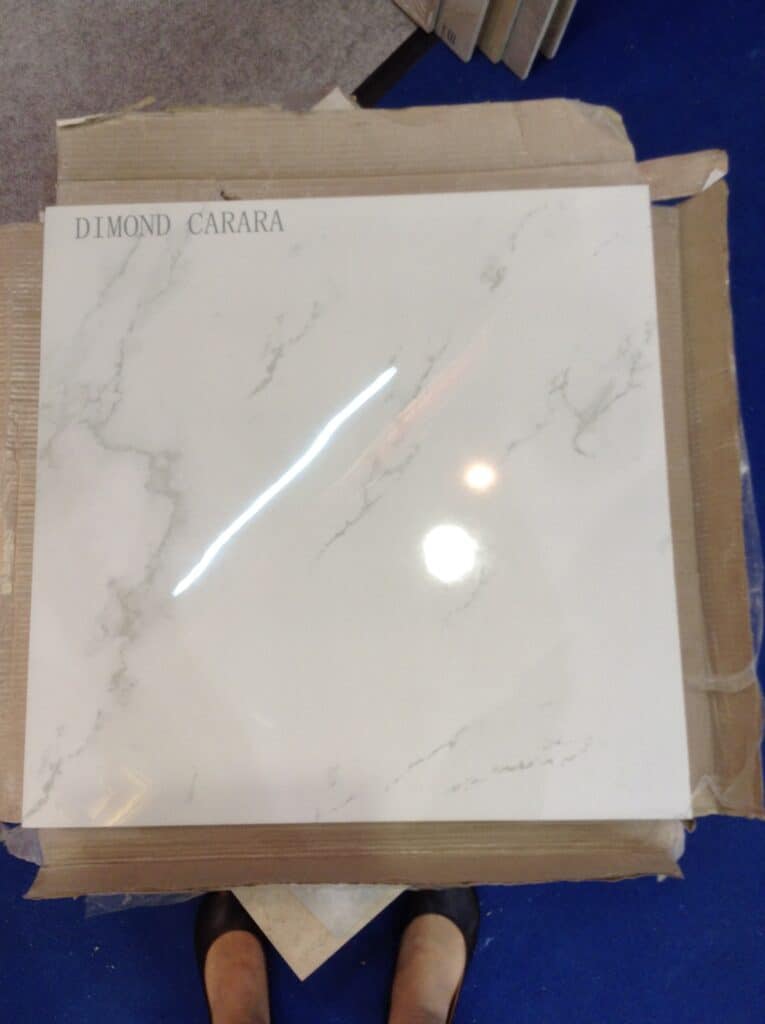

Carrara Marble-look Tile

Pros: The advantages of tile, due to the high-temperature firing, tile material is solid and easy clean, heat resistant, wear resistant, acid and alkali resistant, no water seepage and other advantages, the service life of tile is also relatively long.

Based on our advanced production process, Carrara texture is clearer, with a wide selection of textures, soft and delicate texture, the price is much lower than Carrara marble.

The polished tile‘s surface is brighter and cleaner, which will enhance the brightness of the space in your home after tiling. Glazed tile surface after firing glaze processing, usually glazed tile colour and the pattern is richer. Matte-finished tile is after a thousand degrees of high-temperature firing, the nature of more stable, and a strong historical atmosphere. It can be home to create a nostalgic atmosphere.

Cons: The tiles’ disadvantage is that the pattern is not as “natural” as marble due to the synthetic firing, but we can make each piece of Carrara have a different texture by random printing. And because Carrara tiles are mainly white, its anti-pollution ability is a little less.

Carrara Marble or Carrara Marble-look tile, how to choose?

If you have enough budget and enough time to design the tile-laying, then natural Carrara marble is the best choice for you. When laying, Carrara marble has no gaps, which will give you a better overall effect. Secondly, it is naturally rich in texture; you will not find the same two Carrara marble pieces.

If you are looking for cost effective, want to save time and effort, and want to achieve the natural effect of Carrara by less budget, then Carrara marble-look tile will you be the best choice. Marble tile is much more convenient, with a large choice of texture, strong and durable, and easy to lay. And when they’re laid on the floor, you’ll be hard pressed to tell the difference between the two.

How to identify the quality of Carrara marble-look tile?

Let’s talk about how to identify Carrara marble-look tile, there are several simple methods.

First, whether the texture is clear, there are no trachoma and empty drum, these are the most basic.

Look at the appearance: see whether the surface of the floor tile is smooth and complete, whether the corners are missing, wear; compare two of the same model of floor tile, see the length, height, the texture is the same, splicing two-floor tiles, see whether they can be aligned.

Floor tiles can go on the wall, but wall tiles cannot go down to the floor, you must understand that is wall tiles or floor tiles.

Look at the hardness: scrape the tiles’ surface with a hard small object to see if they are easily scratched.

Identify the tile flatness – four tiles corner to corner put flat, hand touch the middle of the opposite corner, if no which tile warped, are flat.

Identification of tile stain resistance – bring a marker, write on the tile, wait ten minutes later, wipe with a damp cloth, can wipe off the stain resistance is very good.

Identify tile slip resistance – water splashed on, feet on the tile’s surface instead of astringent feeling, is non-slip. Anti-slip and bright matte does not have a relationship; matte tiles are not necessarily anti-slip. It is best to splash water to try, especially in the kitchen and bathroom, to accumulate water and buy a good anti-slip floor tile easily.

What size tile is right for you?

1. Space

Generally speaking, the home living room, walkway, bedroom are more suitable for large size (600mm or more) tiles, kitchen, bathroom and other small spaces recommended to choose a small size (600mm or less) tiles, can increase the coordination of space, and enhance the overall visual effect.

2. Area

Space’s size is also a factor to consider when choosing the tile size; in general, the area of ≤ 30 square meters is recommended to choose 600 × 600 tiles, the area of 30 to 40 square meters is recommended to choose 800 × 800 tiles. In comparison, more than 60 square meters is recommended to choose 600X1200 and 750 × 1500 Carrara marble-look tile. When the kitchen and bathroom space area is large enough, it is recommended to choose 400~600mm tiles, and it is better to choose 300~400mm tiles when the area is too small.

3. Quantity

Due to certain circumstances, home renovation may lead to some loss of tiles, in the purchase is recommended to buy 5% more based on the total amount to ensure enough. Space has a corner, rounded and other situations; the loss will be more. Usage formula: room area ÷ each tile area × (1 + 5% loss amount) = the number of tiles required.

Here is a little extra topic, some people say Carrara marble-look tile paving will have thermal expansion and contraction or uneven problems, then I am sure to tell you that this is the problem of laying technology, if you also have such doubts, you can contact us, we will give you professional advice.

The problems that may arise with Carrara marble-look tile and how we solved them.

We have been making Carrara marble-look tile series for more than 8 years, and during this time we have found some problems and solved them continuously. Many factories may not want to share these problems with you, because they are, in a sense factory secret.

But we think you will be better able to avoid them in your future choices through the cases we share.

1. Texture.

When we first started to produce Carrara marble-look tile around 11 years ago, because we were still using traditional roller printing, its texture was not very clear. It would be blurred, not up to the comfort of natural texture. After a period of experimentation, we found the problem. The traditional roller printing technology could not meet this high definition requirement of the product, so in 2014 we put on a set of advanced inkjet printers with high-quality tile inks, so we started our production of high-quality Carrara.

So when looking for Carrara tile, be sure to pay attention to the tile texture’s clarity. Both the printing method/equipment and the tile ink will affect the rendering of the texture, directly affecting your customer’s feeling of experience.

2. Color difference.

Chromatic aberration is a topic of great concern to every tile factory and every tile distributor, it is Irremovable, but we can intervene in some ways to reduce its impact.

First of all, it is important to understand how the problem of colour difference arises. There are two aspects: the raw material of the tile will show different colours at different temperatures during the firing process, or because of the instability of the inkjet equipment, which produces the colour difference.

Regarding the first aspect, the colour difference occurs because the quality of the wall’s raw material and floor tiles cannot be kept constant—the parameters of the production process change (such as boiler temperature, etc.). Even because the weather suddenly becomes colder or higher will also affect the kiln’s temperature and thus cause colour difference, so it is unavoidable and can only be controlled.

We have been making technical improvements during our 20 years in the industry and trying to eliminate this problem. First of all, with the line workers according to the tiles’ colour into the colour shade, the same colour shade products can not see the obvious colour differences. Secondly, the technical level is constantly updated to control the stability of the kiln temperature.

The second aspect, this is about the factory’s responsibility and cost issues, regular maintenance of equipment maintenance, and renewal and replacement following time can eliminate this part of the impact that may be caused. So the colour difference is an inevitable problem, but according to the factory’s responsibility to compress its impact to a minimum.

3. Flatness

First of all, this is a problem of Carrara series and a problem that cannot be eliminated in the tile industry, which is similar to the problem of colour difference, which also occurs when different raw materials are mixed and then fired.

This problem is about 2 aspects: the technical level and one is the management level. How do we solve it? The first level – technical aspects, the biggest problem is the tile body’s raw material; the different raw material formula will directly affect the tile’s flatness. There is also the temperature of the kiln will also have an impact. The second level – management level, the production process cannot be eliminated; it is necessary to have a strict quality inspection team, in the sorting step to remove the unqualified products.

With 20 years of experience in the industry, we have our own unique formula, high-quality raw materials and reasonable ratios, which allow us to control the flatness to a great extent in the brick embryo process. In terms of management, we always believe that product quality is our foundation, so we always strictly require our quality inspection department not to let go of any defects.

4. Black spots

This problem is caused by many factors, such as raw material impurities, workshop brought in, kiln fall impurities, etc. The main reason is that the raw material contains iron. Carrara this kind of white tiles, the appearance of black spots is a fatal problem. Many people may not care about this problem, and the factory will not take the initiative to raise this issue. But this is a problem that we found in our long working hours and need to share with you.

How do we solve this problem? First of all, we ensure our raw materials’ quality and stability, which is the most fundamental factor. Then to ensure the cleanliness of the production environment. Finally, when black spots appear on the tiles in production, we will classify all the tiles in this batch as substandard products and not sell them to the public.

Tile in the production process there are many uncontrollable factors, this factor will cause some problems that cannot be eliminated, if you want to buy tile, you must understand these problems, understand the problems that arise which should not appear but appear, which is within the acceptable range, understand these, you can make a better choice. T&A Ceramics is not afraid to show these problems to everyone, because we have constantly been working to solve problems.

How to use Carrara Marble-look Tile?

Its white background colour, texture and bright texture make the space more peaceful and elegant; white is a versatile colour and can be matched with any colour, with a lot of room to play; Carrara is more suitable for modern decoration style, because of its quiet, elegant, soft, simple decoration style, loved by modern young people, modern, simple style reveals a low-key luxury beauty. Recommended use: indoor floors and walls of home such as living room, bedroom, bathroom, shower room and kitchen; the projects such as restaurant, hospital, school and offices, etc; backsplash, counter tops stair treads, etc..

Finally, we would like to show some of our laying designs, which we hope will give you some inspiration.

This concludes our 2020 Carrara guide, if you have any questions or are interested in anything, please contact us. T&A Ceramics is a 20-year-old tile manufacturing company, and we will produce Carrara marble-look wall, floor and mosaic tiles with enough experience, advanced production process and strong responsibility, welcome to buy!